Produk

Berikut Produk dan Layanan dari PT. Beringin Asri Sejahtera ;

ASPHALT

ASPHALT BUTON

BIO-DESALINATION

PBD - PRODUCT BIODESALINATION

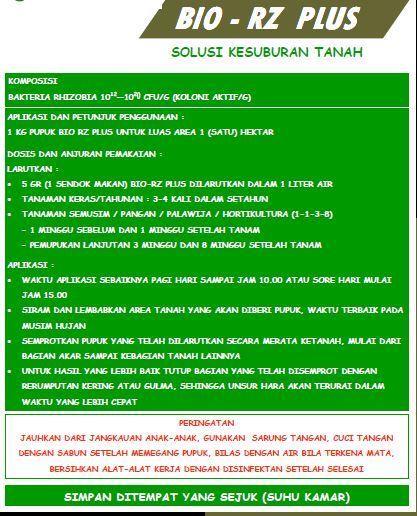

BIO-FERTILIZER

RHIZOBIUM/PUPUK HAYATI

BERN BIONUT/PUPUK ORGANIK

BIO-REMEDIASI

PRODUCT BIOREMEDIASI

FITOREMEDIASI

CHEMICAL CLEANING

CHEM CLEANING

ENHANCED OIL RECOVERY

PRODUCT MEOR

ENZYM

ENZYM

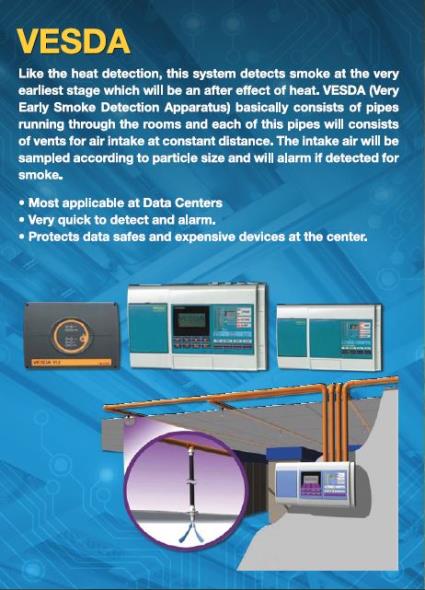

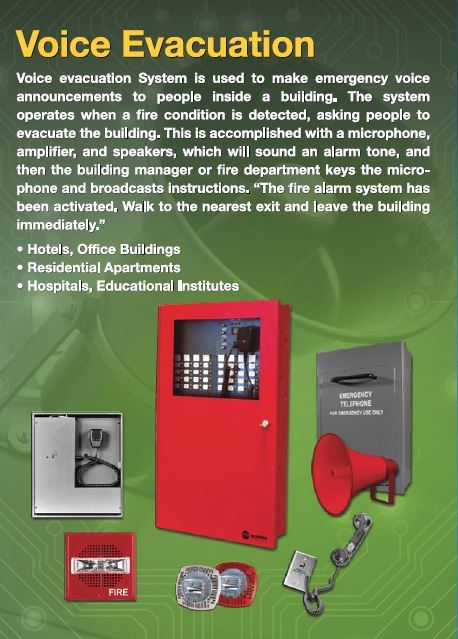

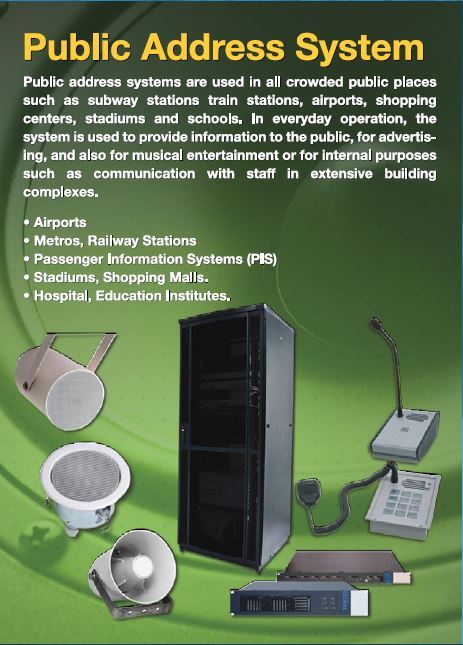

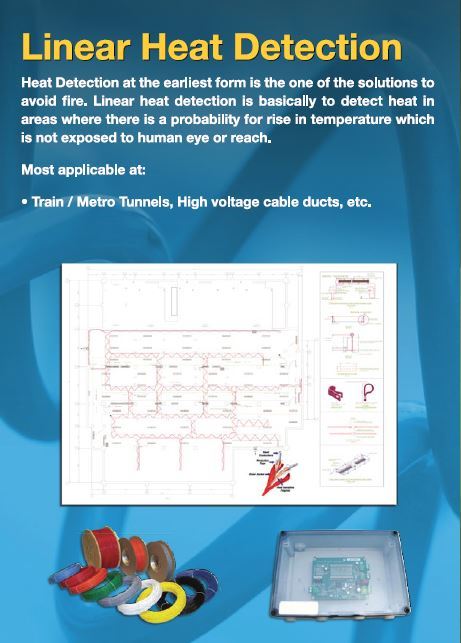

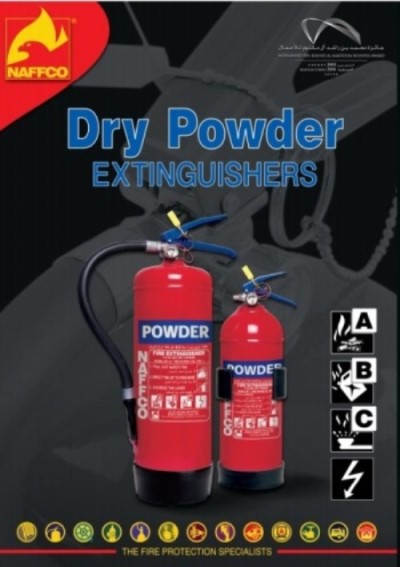

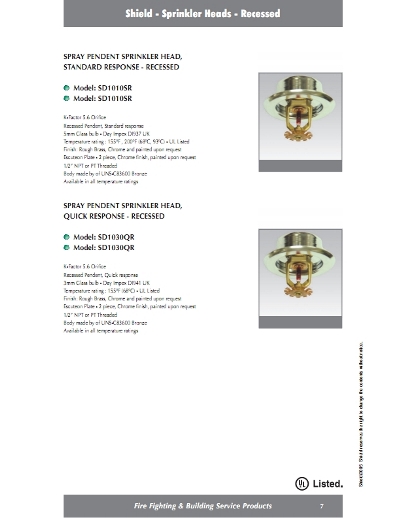

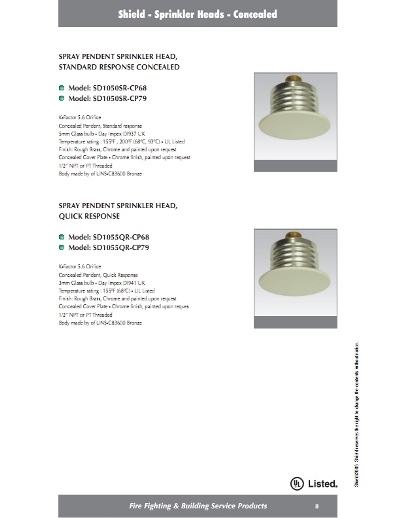

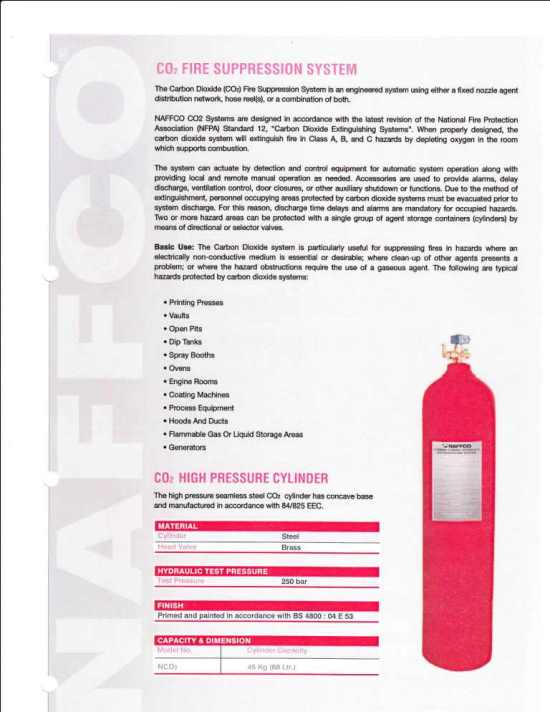

FIRE PROTECTION AND SAFETY ENGINEERING

Fire Extinguisher - Clean Agent Fire CO2 Extinguishers

FIRE EXTINGUISHERS STORED PRESSURE.jpg) | MOBILE CLEAN AGENT (HFC-236FA) FIRE EXTINGUISHERS STORED PRESSURESpecifications :

| |||||||||||||||||||||||||||||||||

FIRE EXTINGUISHERS.jpg) | PORTABLE CLEAN AGENT (HFC-236FA) FIRE EXTINGUISHERSProduct Description : NAFFCO clean agent extinguishers have an effective extinguishing action, environmentally acceptable and excellent alternative for Halon 1211. Clean Agent (HFC-236fa) is a non corrosive, electrically non conductive and free of residue.It is ideally suited for protecting high value equipment. Specifications :

Features :

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fire Extinguisher - Portable Foam Extinguisher

| FOAM MASTER FIRE EXTINGUISHERSpecifications : Specifications :

Features :

Features :

| |||||||||||||||||||||||||||||||

| MOBILE FOAM (AFFF) EXTINGUISHERS : STORED PRESSUREStored Pressure :

External CO2 Cartridge :

Features :

Options :

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| PORTABLE FOAM (AFFF) EXTINGUISHERS : INTERNAL CO2 CARTRIDGESpecifications :

Features :

| |||||||||||||||||||||||||||||||||||||

| PORTABLE FOAM (AFFF) EXTINGUISHERS : STORED PRESSURESpecifications :

DESCRIPTION : AFFF extinguishers are suitable for both Class A & B fires. Foam has the ability to reduce the risk of reignition. Foam extinguishers combine the smothering effect of AFFF and the cooling and penetrating effect of water. Features :

Applications :

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| PORTABLE FOAM (AFFF) EXTINGUISHERS : EXTERNAL CO2 CARTRIDGEIntroduction This package consists of one main pump coupled to electric motor, one stand by pump coupled to diesel engine, jockey pump, pressure vessel, controller (s) for manual or automatic operation of system and standard accessories mounted on base frame(s). The electric pump shall be End Suction or Single Stage Horizontal split case multi stage or Horizontal multi stage centrifugal depending on the System capacity and head requirements. Electric motor is squirrel cage industrial type and foot mounted suitable for 3 phase, with required hose power rating. The diesel engine is fixed on the base with anti-vibration rubber pads and the pump is directly coupled to a diesel engine through flexible coupling, According to the power output of the engine the electrical system can be either 12V or 24 DC. The diesel engine consists of alternator, started motor, fuel system, lubricating system, exhaust system, etc. The jockey pump is vertically mounted multi stage pump coupled to TEFC, 3 phase motor. The controller shall be either common or individual (1 Electric + Diesel & Jockey) and is fabricated from mild steel and epoxy powder coated to red color. The enclosure is IP 54 rated and having all the required controls complying with the applicable standard (NFPA, LPCB, Local Jurisdiction Authority requirements etc.). The standard Fire Pump set will be compete with pressure switches, pressure gauge, suction & discharge manifolds with gate valves & non-return valves, flexible connectors, battery set for diesel engine etc. All are mounted on a strong common bas frame of mild steel and painted red. This Fire Pump set is designed to be installed with the following Fire Protection Systems. The common controller is fabricated from mild steel and epoxy powder coated to red color. The enclosure id IP 54 rated and having all the required controls complying with the applicable standards (NFPA, LPCB Local Jurisdiction Authority requirements etc.). The standard Fire Pump set will be complete with pressure switches, pressure gauge, suction & discharge manifolds with gate valves & non-return valves, flexible connectors, battery set for diesel engine etc. All are mounted on a strong common bas frame of mild steel and painted red. This fire pump set is intended to be used with following Fire Protection System. Description

Specifications

NPS Series Standard Models |

Fire Extinguisher - Water Fire Extinguisher

| MOBILE EXTINGUISHERS – STORED PRESSURESPECIFICATIONS:

Features :

Options :

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| MOBILE EXTINGUISHERS – EXTERNAL CARTRIDGESPECIFICATIONS:

Features :

Options :

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| PORTABLE WATER EXTINGUISHERS – STORED PRESSURE - CARTRIDGE TYPESPECIFICATIONS:

Features :

Options : | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

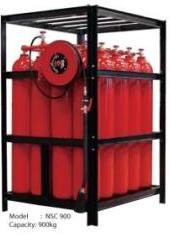

Fire Extinguisher - CO2 Extinguisher

| CO2 MULTIPLE CYLINDER WITH HOSE REELSpecifications :

Features :

| |||||||||||||||||||||||||||||

| CO2 SELF-EXPELLING EXTINGUISHERThese quality fire extinguisher models are extremely versatile and ready to tackle flammable liquid and electrical fire hazards.They are ideally suited for indoor applications where delicate equipment or rocesses require a clean extinguishing agent. Carbon Dioxide is an effective and clean gaseous extinguishing agent that does not leave any residue to clean up. These models are suitable for use on Class B and C fires. Carbon Dioxide Extinguishers – Features :

|

| MOBILE CARBON DIOXIDE EXTINGUISHERSSingle Cylinder :

Double Cylinder :

Options : Carbon dioxide trolley with special discharge hose and horn to use in high reach hazardous area is also available. Special nozzle for aircraft protection is available upon request. Features :

Applications :

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| PORTABLE CARBON DIOXIDE EXTINGUISHERSSPECIFICATIONS:

Description : Carbon dioxide gives fast, safe and effective protection for fires involving electrical equipment and flammable liquids. CO2 is recognised for its non-damaging, highly effective performance and cleanliness. They are generally suited for indoor use, making them ideal for today’s office environments. Features :

Applications :

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SKID MOUNTED CO2 EXTINGUISHING SYSTEMThese quality fire extinguisher models are extremely versatile and ready to tackle flammable liquid and electrical fire hazards.They are ideally suited for indoor applications where delicate equipment or rocesses require a clean extinguishing agent. Carbon Dioxide is an effective and clean gaseous extinguishing agent that does not leave any residue to clean up. These models are suitable for use on Class B and C fires. Carbon Dioxide Extinguishers – Features :

|

Fire Extinguisher - Wet Chemical Fire Extinguisher

| Wet Chemical Fire ExtingusherStored Pressure Fire Extinguisher : Fire extinguishing agents have different reaction to sources of fire making the choice of a fire extinguisher dependent on the application and effectiveness in minimizing fire damage. NAFFCO wet chemical extinguishers are ideal for Class F fires, involving cooking oils and fats. It is extremely effective as the wet chemical rapidly knocks the flames out, cools the burning oil and chemically reacts to form a soap-like solution, sealing the surface and preventing re-ignition. NAFFCO wet chemical extinguishers are easy to use producing a gentle but highly effective spray. The gentle application helps prevent hot oil splashing onto the user. An added benefit is that it is also suitable for freely burning materials (Class A) such as wood paper and fabrics. FEATURES :

Technical Specifications:

|

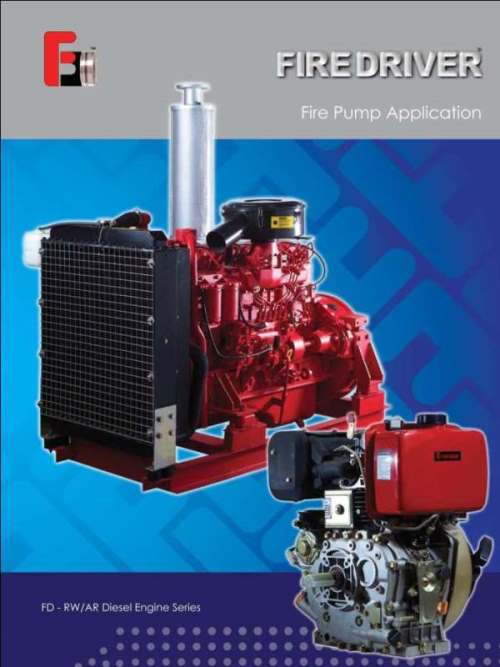

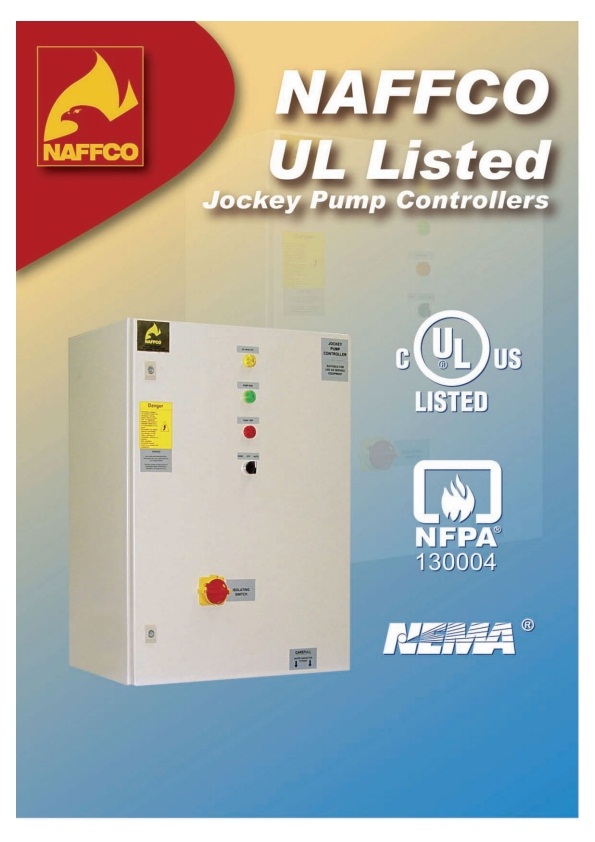

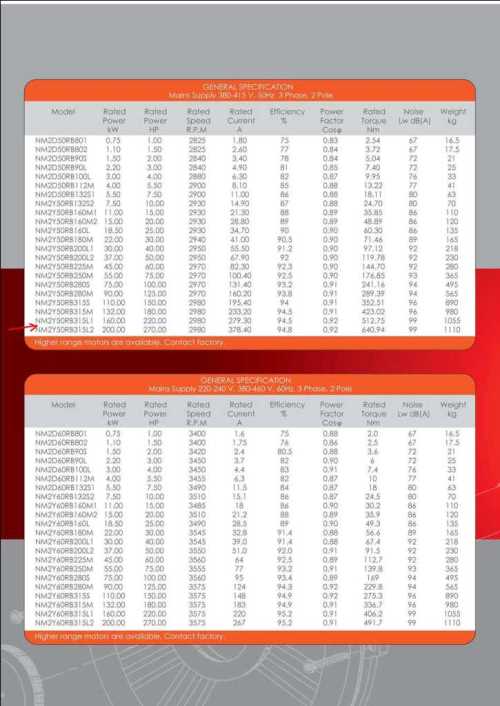

Fire Pump - Standard Fire Pump

| NAFFCO FIRE PUMP SET MODEL NPE SERIESThis package consists of 2 electric motor driven fire pumps, (one is duty and another one is standby), jockey pump, pressure vessel, suction and discharge manifold, discharge pressure gauge, pressure switches, common controller for manual or auto operation of the system, standard accessories and base frame(s). The fire pumps shall be end suction or horizontal split case or horizontal multistage type. The electric motor is squirrel cage induction type and foot mounted suitable for 3 phase supply. Jockey pump shall be vertical multistage type close coupled to electric motor. Description :

Specifications

Note: Higher ranges are available upon request |

| NAFFCO FIRE PUMP SET MODEL NPS SERIESIntroduction This package consists of one main pump coupled to electric motor, one stand by pump coupled to diesel engine, jockey pump, pressure vessel, controller (s) for manual or automatic operation of system and standard accessories mounted on base frame(s). The electric pump shall be End Suction or Single Stage Horizontal split case multi stage or Horizontal multi stage centrifugal depending on the System capacity and head requirements. Electric motor is squirrel cage industrial type and foot mounted suitable for 3 phase, with required hose power rating. The diesel engine is fixed on the base with anti-vibration rubber pads and the pump is directly coupled to a diesel engine through flexible coupling, According to the power output of the engine the electrical system can be either 12V or 24 DC. The diesel engine consists of alternator, started motor, fuel system, lubricating system, exhaust system, etc. The jockey pump is vertically mounted multi stage pump coupled to TEFC, 3 phase motor. The controller shall be either common or individual (1 Electric + Diesel & Jockey) and is fabricated from mild steel and epoxy powder coated to red color. The enclosure is IP 54 rated and having all the required controls complying with the applicable standard (NFPA, LPCB, Local Jurisdiction Authority requirements etc.). The standard Fire Pump set will be compete with pressure switches, pressure gauge, suction & discharge manifolds with gate valves & non-return valves, flexible connectors, battery set for diesel engine etc. All are mounted on a strong common bas frame of mild steel and painted red. This Fire Pump set is designed to be installed with the following Fire Protection Systems. The common controller is fabricated from mild steel and epoxy powder coated to red color. The enclosure id IP 54 rated and having all the required controls complying with the applicable standards (NFPA, LPCB Local Jurisdiction Authority requirements etc.). The standard Fire Pump set will be complete with pressure switches, pressure gauge, suction & discharge manifolds with gate valves & non-return valves, flexible connectors, battery set for diesel engine etc. All are mounted on a strong common bas frame of mild steel and painted red. This fire pump set is intended to be used with following Fire Protection System. Description

Specifications

NPS Series Standard Models

|

| NAFFCO FIRE PUMP SET MODEL NPH SERIESIntroduction The fire pumps are the heart of any liquid based Fire Fighting System and we at NAFFCO ensures the proper functioning of this heat by the excellent design, manufacturing & installation. We use the expertise of our well experienced engineers and designs each pump sets to suit the specific Fire Fighting System requirements, site conditions and the relevant standards. The quality of design is maintained throughout the process of manufacturing and our customers get 100% reliable pump set. Each pumps sets are being tested for the performance as per the designed system requirements before dispatching from the factory. Being a UL registered firm, we implements stringent quality measures throughout the production which enables us to achieve the desired performance standards conforming to different regulations of NFPA, LPCB and Local Jurisdiction Authorities. The ISO 9001:2000 certification by LPCB testifies to these facts. The pumps delivered by us are covered by a standard warranty of one year. Currently around 20,000 NAFFCO packaged Fire Pump Set are working worldwide in Government buildings, Warehouses, High rise Building, Factories, Residential buildings, etc. to protect the precious life and properties. This model consist of one eclectic motor driven Fire Pump, diesel engine driver Fire Pump, one common Fire Pump controller, pressure vessel and standard accessories mounted on base frame. The electric pump shall be vertical multistage type close coupled to electric motor. The electric motor is squirrel cage industrial type, suitable for 3 phase, with required horse power rating. The diesel engine is fixed on the base with anti-vibration rubber pads and the pump is close (up to 50gpm @ 5 bar)/ flexibly (above 50 gpm @ 5 bar) coupled to diesel engine. According to the power output of the engine the electrical system can be either 12V or 24V DC. The diesel engine consists of starter motor, fuel system, lubricating system, exhaust system etc The common controller is fabricated from mild steel and epoxy powder coated to red color. The enclosure id IP 54 rated and having all the required controls complying with the applicable standards (NFPA, LPCB Local Jurisdiction Authority requirements etc.). The standard Fire Pump set will be complete with pressure switches, pressure gauge, suction & discharge manifolds with gate valves & non-return valves, flexible connectors, battery set for diesel engine etc. All are mounted on a strong common bas frame of mild steel and painted red. This fire pump set is intended to be used with following Fire Protection System. Data Of Performance Range For Fire Pump Set Model NPH Series

NPH Series Standard Models

Note: Fire Pump sets are available for other duty points and higher ranges also. Please contact factory. |

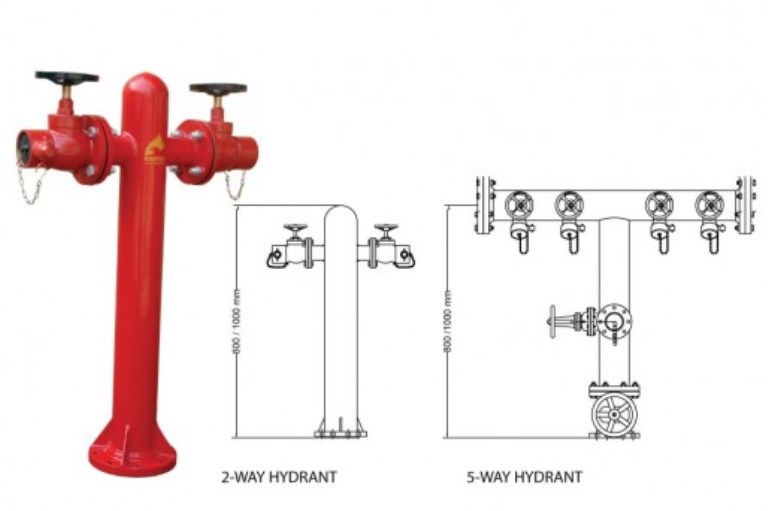

Fire Hydrant & Equipment - Dry Type Fire Hydrant

| DRY TYPE FIRE HYDRANTSBill Of Material : Item No Description

NFH Series Fire Hydrants

Features :

Specifications :

Material

| |||||||||||||||||||||||||||||||||||||||||||||||||||||

Fire Hydrant & Equipment - Hydrant Cabinet

| HYDRANT CABINETSpecifications :

Specifications :

|

Fire Hydrant & Equipment - LPCB Approved Dry Pillar Fire Hydrants

| LPCB APPROVED DRY PILLAR FIRE HYDRANTS

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fire Hydrant & Equipment - Dry Type Fire Hydrant With Security System

| DRY TYPE FIRE HYDRANT WITH SECURITY CAPSpecifications

Features :

Bill Of Material :

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fire Hydrant & Equipment - Wet Type Fire Hydrant Pedestal - Type

| WET TYPE FIRE HYDRANT PEDESTAL-TYPEBill Of Material :

Optional :

|

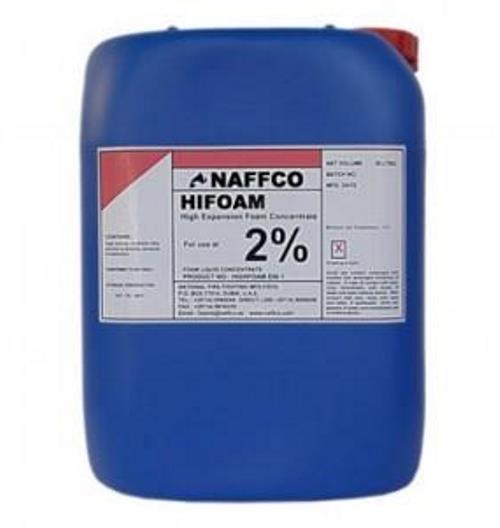

Suppresion System - Foam System & Concentrates

| FOAM CONCENTRATES - FILMPLUS AR (3X6) AFFF-AR (UL LISTED)DESCRIPTION Filmplus AR(3X6) is an high efficiency multi purpose alcohol resistant film forming foam, 3 X 6 type. The film forming characteristics of Filmplus AR(3×6) means that it spreads rapidly across a fire. As a result, it is highly effective against hydrocarbon fires and with the addition of special polymers it is also highly effective against polar solvents. When used in an emergency, it generates a free flowing cohesive foam blanket with excellent burn back resistance. It is intended for use at a proportioning rate of 3% when used on hydrocarbon fuels such as gasoline, diesel, jet fuel or kerosene. On water miscible / polar solvent type fuels such as alcohols, ketones esters etc. It is intended for use at 6% proportioning rate. FEATURES

PROPORTIONING Filmplus AR(3X6) is designed for use with the following types of proportioning equipment.

DISCHARGE DEVICES Filmplus AR(3X6) is suitable for use with the following discharge devices.

APPLICATIONS Filmplus AR(3X6) will provide quality protection for a wide range of hazardous areas such as:

TYPICAL SPECIFICATION

FOAMING PROPERTIES When Filmplus AR(3X6) is mixed with water in the correct proportions, air aspirating type discharge devices will typically generate an expansion ratio of between 5-10 to 1. Non-aspirating devices will typically generate expansion ratios of between 2-4 to 1. Expansion ratios are dictated by the discharge device, flow rate and discharge pressure. PERFORMANCE To ensure reliable fire fighting, the performance of Filmplus AR(3X6) is measured against a 50 ft2 heptane fire at 0.10 gmpm/ft2, and on IPA at 0.17 gpm/ft2 ENVIRONMENTAL IMPACT Filmplus AR(3X6) is biodegradeable, low in toxicity and can be treated in sewage treatment plants. STORAGE AND HANDLING If kept in the original unopened and air tight container and stored within the temperature range of 00C to +500C, a shelf life of approximately 20 years can be expected.

If the Filmplus AR(3X6) is to be stored in an atmospheric type foam concentrate storage tank whether on mobile apparatus or stationary, limit the air space above the surface of the concentrate where possible and place a thin layer of quality mineral oil on the surface of the foam concentrate to minimize any effect from evaporation. ORDERING INFORMATION Filmplus AR(3X6) is available in 20 Liter Jerry Cans or 200 Liter drums. Other packings as per customer requirements can also be done. Part No. Filmplus AR(3X6)- J 20L Part No. Filmplus AR(3X6)- D 200L |

.jpg) | FOAM CONCENTRATES - FILMPLUS NF3UL AFFF 3% (UL LISTED)DESCRIPTION Filmplus NF3 UL AFFF 3% is a superior quality aqueous film forming foam, which can be used at 3%concentration to extinguish fires of non-polar hydrocarbon fuels. Filmplus NF3 UL AFFF 3% is suitable for use with most types of proportioning and discharge equipment. AFFF foam concentrates are designed for rapid fire knockdown by producing a thin aqueous film which helps to prevent the release of fuel vapours. The foam blanket from which the film forming liquid drains separates oxygen from the fuel surface, extinguishes the fire and prevents re-ignition. The water content of the foam provides a cooling effect. The aqueous film is produced by the fluorocarbon surfactant reducing the surface tension of the foam solution to a point where the solution can be supported by the surface tension of the fuel. Filmplus NF3 UL AFFF 3% provides excellent penetrating and wetting qualities when used on Class A fires. This is important when extinguishing deep-seated fires in wood, paper, rubber and other ordinary combustibles. FEATURES

PROPORTIONING Filmplus NF3 UL AFFF 3% is designed for use with the following types of proportioning equipment.

DISCHARGE DEVICES Filmplus NF3 UL AFFF 3% is suitable for use with the following discharge devices.

APPLICATIONS Filmplus NF3 UL AFFF 3% will provide quality protection for a wide range of hazardous areas such as:

TYPICAL SPECIFICATION

PERFORMANCE The fire performance of Filmplus NF3 UL AFFF 3% is measured against Underwriters Laboratories Standard UL 162-7th Edition. ENVIRONMENTAL IMPACT Filmplus NF3 UL AFFF 3% is biodegradable, low in toxicity and can be treated in sewage treatment plants. STORAGE AND HANDLING Filmplus NF3 UL AFFF 3% may be stored in its shipping container without change in its original physical or chemical characteristics. Shelf life is expected to be 10 years or more when stored at recommended temperatures and in original containers. It does not show significant sedimentation or precipitation in storage or after temperature cycling. Freezing and thawing have no effect on performance and the concentrate proportions satisfactorily in ordinary equipment at temperatures above +20C. Synthetic foam concentrates should only be stored in stainless steel(Type 304L or 316), reinforced fiberglass polyester with a vinyl ester resin internal layer coating or plastic containers. ORDERING INFORMATION Filmplus NF3 UL AFFF 3% is available in 20 Liter Jerry Cans or 200 Liter drums. Other packings as per customer requirements can also be done. Part No. Filmplus NF3 UL AFFF 3%- J 20L Part No. Filmplus NF3 UL AFFF 3%- D 200L |

.jpg) | FOAM CONCENTRATES - FILMPLUS NF6 UL AFFF 6% (UL LISTED)DESCRIPTION Filmplus NF6 UL AFFF 6% is a superior quality aqueous film forming foam, which can be used at 6%concentration to extinguish fires of non-polar hydrocarbon fuels. Filmplus NF6 UL AFFF 6% is suitable for use with most types of proportioning and discharge equipment. AFFF foam concentrates are designed for rapid fire knockdown by producing a thin aqueous film which helps to prevent the release of fuel vapours. The foam blanket from which the film forming liquid drains separates oxygen from the fuel surface, extinguishes the fire and prevents re-ignition. The water content of the foam provides a cooling effect. The aqueous film is produced by the fluorocarbon surfactant reducing the surface tension of the foam solution to a point where the solution can be supported by the surface tension of the fuel. Filmplus NF6 UL AFFF 6% provides excellent penetrating and wetting qualities when used on Class A fires. This is important when extinguishing deep-seated fires in wood, paper, rubber and other ordinary combustibles. FEATURES

PROPORTIONING Filmplus NF6 UL AFFF 6% is suitable for use with the following discharge devices

DISCHARGE DEVICES Filmplus NF6 UL AFFF 6% is suitable for use with the following discharge devices.

APPLICATIONS Filmplus NF6 UL AFFF 6% will provide quality protection for a wide range of hazardous areas such as:

TYPICAL SPECIFICATION

PERFORMANCE The fire performance of Filmplus NF6 UL AFFF 6% is measured against Underwriters Laboratories Standard UL 162-7th Edition. ENVIRONMENTAL IMPACT Filmplus NF6 UL AFFF 6% is biodegradable, low in toxicity and can be treated in sewage treatment plants. STORAGE AND HANDLING Filmplus NF6 UL AFFF 6% may be stored in its shipping container without change in its original physical or chemical characteristics. Shelf life is expected to be 10 years or more when stored at recommended temperatures and in original containers. It does not show significant sedimentation or precipitation in storage or after temperature cycling. Freezing and thawing have no effect on performance and the concentrate proportions satisfactorily in ordinary equipment at temperatures above +2C. Synthetic foam concentrates should only be stored in stainless steel(Type 604L or 616), reinforced fiberglass polyester with a vinyl ester resin internal layer coating or plastic containers. ORDERING INFORMATION Filmplus NF6 UL AFFF 6% is available in 20 Liter Jerry Cans or 200 Liter drums. Other packings as per customer requirements can also be done. Part No. Filmplus NF6 UL AFFF 6%- J 20L Part No. Filmplus NF6 UL AFFF 6%- D 200L |

.jpg) | FOAM CONCENTRATES - FLUOROFOAM 3PUL 3% FLUOROPROTEIN FOAM (UL LISTED)DESCRIPTION Fluorofoam 3PUL is a fluoroprotein foam concentrate containing fluorinated surfactants in a carefully formulated protein foam liquid base. This ensures the production of a stabilised fluid foam which will cover a burning hydrocarbon fuel surface very rapidly. The water soluble fluorosurfactant makes the foam hydrocarbon repellent and reduces the amount of burning particles absorbed by the foam in fighting the hydrocarbon fuel fires. Once fire extinction has been achieved the high stability of the foam blanket ensures against the risk of re-ignition and provides excellent protection against ‘burn-back’ should any inaccessible pockets of fire remains. Fluorofoam 3PUL should be used as a 3% proportioned solution in fresh or sea water. It may be also used and stored as 3% pre-mix in fresh/potable water. The correct proportioning or mixture ratio is 3 parts of concentrate and 97 parts of water. FEATURES

PROPORTIONING Fluorofoam 3PUL is designed for use with the following types of proportioning equipment.

DISCHARGE DEVICES Fluorofoam 3PUL is recommended for use with the following air-aspirating discharge devices.

APPLICATIONS Fluorofoam 3PUL will provide quality protection for a wide range of hazardous areas such as:

TYPICAL SPECIFICATION

FOAMING PROPERTIES The foaming properties/expansion will vary depending on the type of discharge equipment, inlet pressure and flow rate. The minimum expansion would be at least 7 to 1 and the 25% drainage time would be not less than 3 minutes. PERFORMANCE Fluorofoam 3PUL is biodegradable, low in toxicity and can be treated in sewage treatment plants. ENVIRONMENTAL IMPACT Filmplus AR(3X3) is biodegradeable, low in toxicity and can be treated in sewage treatment plants. STORAGE AND HANDLING When stored in the drums supplied the material has a long shelf life. The minimum and maximum usable temperatures for Fluorofoam 3PUL concentrate are -50C and +500C respectively and shelf life should be 10 years when stored in original containers. As with all protein based materials, shelf life will be dependent on storage or transportation, thawing will render the product completely usable. Fluorofoam 3PUL may be stored in plastic or SS304 or FRP Containers. For bulk storage, mild steel tanks may be used provided the internal surface is coated with a protective coating such as epoxy. The use of galvanised material should be avoided for storage vessels and pipework involving the concentrate. ORDERING INFORMATION Fluorofoam 3PUL is available in 20 Liter Jerry Cans or 200 Liter drums. Other packings as per customer requirements can also be done. Part No. Fluorofoam 3PUL- J 20L Part No. Fluorofoam 3PUL- D 200L |

.jpg) | FOAM CONCENTRATES - FLUOROFOAM 6PUL 6% FLUOROPROTEIN FOAM (UL LISTED)DESCRIPTION Fluorofoam 6PUL is a fluoroprotein foam concentrate containing fluorinated surfactants in a carefully formulated protein foam liquid base. This ensures the production of a stabilised fluid foam which will cover a burning hydrocarbon fuel surface very rapidly. The water soluble fluorosurfactant makes the foam hydrocarbon repellent and reduces the amount of burning particles absorbed by the foam in fighting the hydrocarbon fuel fires. Once fire extinction has been achieved the high stability of the foam blanket ensures against the risk of re-ignition and provides excellent protection against ‘burn-back’ should any inaccessible pockets of fire remains. Fluorofoam 6PUL should be used as a 6% proportioned solution in fresh or sea water. It may be also used and stored as 6% pre-mix in fresh/potable water. The correct proportioning or mixture ratio is 6 parts of concentrate and 97 parts of water. FEATURES

PROPORTIONING Fluorofoam 6PUL is designed for use with the following types of proportioning equipment.

DISCHARGE DEVICES Fluorofoam 6PUL is recommended for use with the following air-aspirating discharge devices.

APPLICATIONS Fluorofoam 6PUL will provide quality protection for a wide range of hazardous areas such as:

TYPICAL SPECIFICATION

FOAMING PROPERTIES The foaming properties/expansion will vary depending on the type of discharge equipment, inlet pressure and flow rate. The minimum expansion would be at least 7 to 1 and the 25% drainage time would be not less than 3 minutes. PERFORMANCE Fluorofoam 3PUL is biodegradable, low in toxicity and can be treated in sewage treatment plants. ENVIRONMENTAL IMPACT Filmplus AR(6X6) is biodegradeable, low in toxicity and can be treated in sewage treatment plants. STORAGE AND HANDLING When stored in the drums supplied the material has a long shelf life. The minimum and maximum usable temperatures for Fluorofoam 6PUL concentrate are -50C and +500C respectively and shelf life should be 10 years when stored in original containers. As with all protein based materials, shelf life will be dependent on storage or transportation, thawing will render the product completely usable. Fluorofoam 6PUL may be stored in plastic or SS304 or FRP Containers. For bulk storage, mild steel tanks may be used provided the internal surface is coated with a protective coating such as epoxy. The use of galvanised material should be avoided for storage vessels and pipework involving the concentrate. ORDERING INFORMATION Fluorofoam 6PUL is available in 20 Liter Jerry Cans or 200 Liter drums. Other packings as per customer requirements can also be done. Part No. Fluorofoam 6PUL- J 20L Part No. Fluorofoam 6PUL- D 200L |

| FOAM CONCENTRATES - HIGHFOAM SX HIGH EXPANSION FOAM 1000DESCRIPTION HIGHFOAM SX is a blend of high activity, synthetic, fatty alcohol sulphates, solvents and stabilisers. HIGHFOAM SX mixed with water and converted into finished foam via medium or high expansion foam making equipment combats fires by engulfing the area, restricting the supply of oxygen and creating an inert atmosphere. The water content of the foam, particularly the medium expansion, provides a cooling effect. HIGHFOAM SX should be used between 1% and 3 % concentration in fresh or sea water if medium or high expansion foams are required depending on the equipment used.FEATURES

PROPORTIONING HIGHFOAM SX is designed for use with the following types of proportioning equipment.

APPLICATIONS HIGHFOAM SX will provide quality protection for a wide range of hazardous areas such as:

DISCHARGE DEVICES HIGHFOAM SX is suitable for use with the following discharge devices.

TYPICAL SPECIFICATION

ENVIRONMENTAL IMPACT HIGHFOAM SX is biodegradable, low in toxicity, and can be treated in sewage treatment plants. STORAGE AND HANDLING If kept in the original unopened and air tight container and stored within the temperature range of -30C to +490C, the material has a long shelf life. ORDERING INFORMATION HIGHFOAM SX is available in 20Liter Jerry Cans or 200 Liter drums. Other packings as per customer requirements can also be done. Part No. HIFOAM SX 20L Part No. HIFOAM SX 200L |

AFFF-AR 3PERCENT (UL LISTED) FOAM CONCENTRATES.jpg) | FOAM CONCENTRATES - FILMPLUS AR (3X3) AFFF-AR 3% (UL LISTED)FEATURES

PROPORTIONING Filmplus AR (3X3) is designed for use with the following types of proportioning equipment.

DISCHARGE DEVICES Filmplus AR(3X6) is suitable for use with the following discharge devices.

APPLICATIONS Filmplus AR(3X3) Recommended application rate on hydrocarbon type fuels is 0.10 gpm/ft2 and on polar solvent type fuels is 0.15 gpm/ft2. On the following specific polar solvent type fuels these are the recommended minimum application rates.

TYPICAL SPECIFICATION

FOAMING PROPERTIES Aspirating type discharge devices typically generate expansion ratios between 6-10 to 1 when FilmplusAR(3X3) is mixed with water at the correct ratio. Non-aspirating type devices generate expansion ratios of between 2–4 to 1. Expansion ratios are dictated by the type of discharge device, flow rate and discharge pressure. PERFORMANCE The fire performance of Filmplus AR(3X3) is measured against Underwriters Laboratories Standard UL 162-7th Edition. ENVIRONMENTAL IMPACT Filmplus AR(3X3) is biodegradeable, low in toxicity and can be treated in sewage treatment plants. STORAGE AND HANDLING If kept in the original unopened and air tight container and stored within the temperature range of 00C to 500C, a shelf life of between 20-25 years can be expected.

If the Filmplus AR(3X3) is to be stored in an atmospheric type foam concentrate storage tank whether on mobile apparatus or stationary, limit the air space above the surface of the concentrate where possible and place a thin layer of quality mineral oil on the surface of the foam concentrate to minimize any effect from evaporation. ORDERING INFORMATION Filmplus AR(3X3) is available in 20 Liter Jerry Cans or 200 Liter drums. Other packings as per customer requirements can also be done.

Part No. Filmplus AR(3X3)- J 20L Part No. Filmplus AR(3X3)- D 200L |

Truck & Vehicles - Ambulances

| 4 x 4 AMBULANCESMedical equipments

|

| TYPE II AMBULANCEEQUIPMENT & FEATURES

ELECTRICAL AND WARNING LIGHT

MEDICAL EQUIPMENTS

|

| VAN AMBULANCESMedical equipments

|

Truck & Vehicles - Fire Fighting & Rescue

| AERIAL ACCESS PLATFORMSDescription NAFFCO can offer a wide range of platform from 9 to 35 meters working heights (VERSALIFT Line) under different categories like telescopic, Telescopic Articulated, Articulated over center and Articulated Non-over Center Access Platforms. The platforms can be either non-insulated or insulated, chassis mounted or van mounted or even tracked access platforms. Our platforms meet ANSI standards and are CE approved and are known as reliable, high quality products with low maintenance costs. Exclusive Features Of NAFFCO Aerial Access Platforms

|

| AIRPORT FIRE FIGHTING VEHICLESSPECIFICATIONS AIRPORT RESCUE FIRE FIGHTING VEHICLES (ARFF)

AIRPORT FIRE FIGHTING VEHICLES (AFFV)

|

| INDUSTRIAL FIRE FIGHTING VEHICLESNAFFCO manufacturing department has the latest technology, state-of-art-machines (CNC machines, hydraulic shearing and bending machines, all types of welding machines -MIG,TIG , ARC etc…) and also has a full-fledged machine shop to cater the needs of the production requirements. NAFFCO has the ability to introduce the latest technological systems & equipments in the field , as our engineers and technicians are well qualified & experienced to produce quality products. The department is equipped with full-fledged testing facilities to test the equipment as per NFPA , EN,ICAO , KKK and Civil Defense standards & requirements , and to meet the customers specifications. Considering the above facilities and excellence in engineering capabilities, NAFFCO can meet any challenges to produce bulk quantities of trucks. SPECIFICATION

|

| LADDERS AND PLATFORMSSPECIFICATIONS

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| MEDIUM DUTY FIRE FIGHTING VEHICLE NFM 6050 DCCHASSI MAN TGM 18.240, 4×2, Double Cabin, Manual Transmission, 240 HP, 18,000 KG GVW, other chassis available upon request. BODY STRUCTUREMade using aluminum profiles 6061 T6, fastened to a strong base structure made of stainless steel tubing. WATER & FOAM TANKS6,000/500 Liters made of Polypropylene with life time warranty. STORAGE LOCKERSTwo (2) storage lockers, one on the R/H side and one on the L/H side of the vehicle closed by light alloy roller shutters. FOAM SYSTEMAround-the-Pump Foam Proportioning System 0 – 6 %, Manual adjustable. FIRE PUMPPTO Driven, Single stage, centrifugal type normal pressure pump, 3,000 LPM at 8 Bar and 3 meter suction lift. MONITORWater / Foam Monitor with jet/fog pattern, with adjustable output from 800 lpm to 2,400 lpm and throw range up to 65meters. HOSE REELManual Rewind hose reel fitted with rubber hose of 1.25” x 30m fitted with pistol type nozzle for jet and fog patterns. ACCESSORIESWide range of fire fighting accessories and equipments including hoses, nozzles, SCBA Sets, Generator and personal fire protections sets. |

| RIV AND RESCUERS FIRE FIGHTING VEHICLESSpecifications

All capacities are subject to changes depending on the chassis payload (for Double cabin option, capcities will be reduced)Double cabin option is subject to availability from chassis manufacturer NOTE: ALL PRODUCT SPECIFICATION AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE. RIV & Rescuers vehicle

|

Valves & Riser Equipments

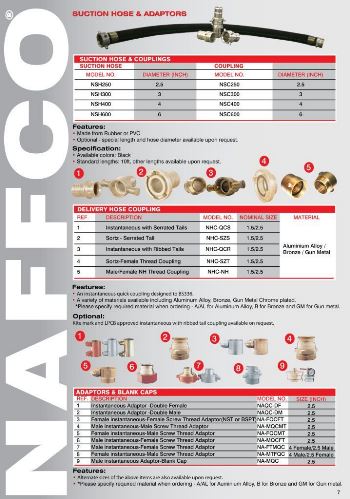

| AIR RELEASE VALVESPECIFICATIONS:

|

| ANGLE HOSE VALVEThe Angle hose valve is manufactured as per NFPA 13 and most suitable for fire protection service outlet or with a hose rack assembly. SPECIFICATIONS:

|

| DIFFUSER NOZZLESDiffuser nozzle has an adjustable annular orifice which enables the jet of water to be controlled from shut-off to small jet through to large jet then to spray pattern by turning of the rubber sleeve. SPECIFICATIONS:

|

| FIRE HOSE CRADLEFire hose is rolled and stored in a swinging cradle and designed for easy access. These cradles are Wall mountable and Cabinet mountable. SPECIFICATIONS:

|

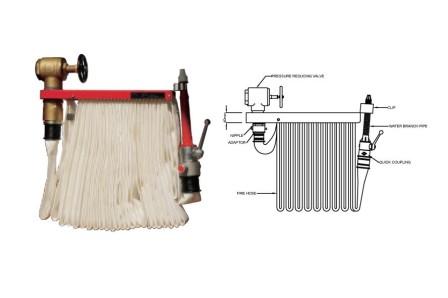

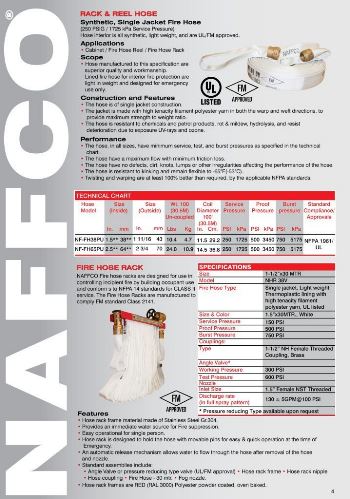

| FIRE HOSE RACKNAFFCO Fire hose rack is located inside buildings at the wet or dry riser outlet. It features a rack in which hangs the lay flat fire hose (30m). An automatic release mechanism allows water to flow through the hose after removal of the hose and nozzle. |

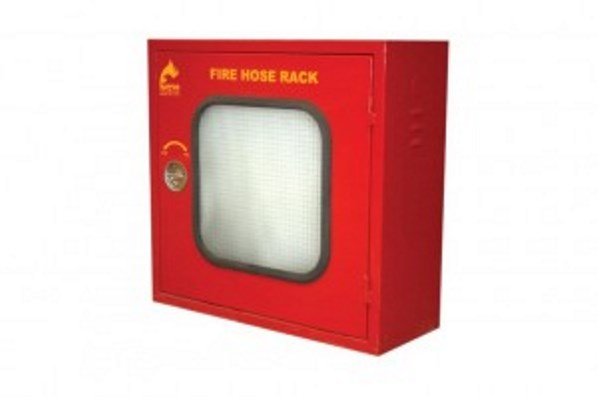

| FIRE HOSE RACK CABINETNAFFCO Fire hose rack cabinet is designed to accomodate complete assembly of fire hose rack. These Cabinets have either solid or wired glass door and are available in surface or recesses mounting version. SPECIFICATIONS:

|

| JET AND SPRAY NOZZLEThis durable, plastic nozzle produces a strong, concentrated jet of water that can fight fires in a most efficient way. Yet it is quickly and easily adjustable from a jet to a diffused spray, or a complete shut off. SPECIFICATIONS:

|

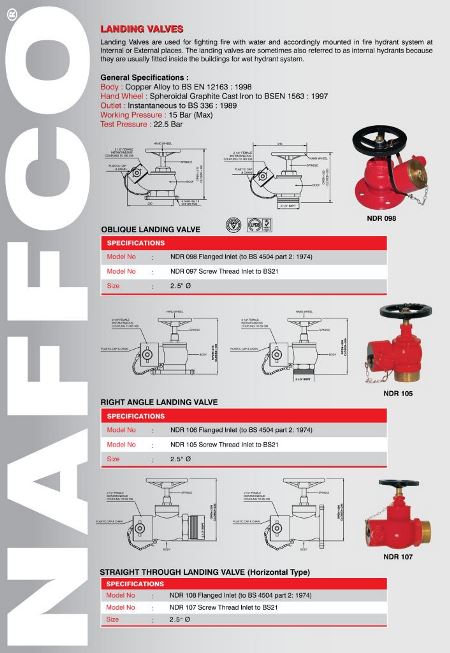

| LANDING - VALVE |

| PRESSURE REGULATING VALVE“E” Type Pressure Regulating Valve NAFFCO’s Pressure reducing oblique landing valves are suitable for installation on wet risers in buildings for fire fighting purposes, permanently charged with water from a pressurized supply.These landing valves are pressure reducing type designed to provide a range of outlet pressure (4 bar – 12 bar).The landing valves are classified under high pressure and are suitable for use at nominal inlet pressure upto 20 bar and for working temperature range from 0 °C to 38 °C. SPECIFICATIONS:

|

| SINGLE CLAPPER TWO WAY INLETSThe clapper design allows for one or both inlets to be pressurized during operation and provide supplementary water supply connection for automatic sprinkler systems as per NFPA 13 SPECIFICATIONS:

|

| WATER CURTAIN NOZZLESPECIFICATIONS:

|

MICROORGANISME

MICROORGANISME CAIR

| BERN MICRO EL3360Bern Micro EL3360 adalah Mikroorganisme yang dikemas dalam bentuk cair yang berfungsi untuk mendegradasi senyawa-senyawa organik pada proses pembuatan kompos. Bern Micro adalah mikroorganisme hasil seleksi yang dapat mempercepat proses pengomposan. Microorganisme ini merupakan mikroorganisme yang dapat melakukan fermentasi terhadap senyawa-senyawa organik melalui kemampuan lignolitik, selulotik, amilolitik, preteolitik serta fiksasi nitrogen nonsimbiotik. Mikroorganisme ini juga dapat melakukan fermentasi senyawa organic didalam tanah menjadi unsur organic, sehingga kesuburan tanah dan produktivitas tanaman bertambah. Aturan Pakai: Terhadap bahan organik yang telah dipersiapkan (bahan organik ukuran ≤ 5cm, pupuk kandang dengan perbandingan 1:3 atau sebaliknya) ditambahkan Bern Micro 0.2 – 1.0%(V or b). |

MICROORGANISME PADAT

| BERN MICRO ES3360Bern Micro ES3360 adalah Microorganisme yang dikemas dalam bentuk padat yang berfungsi untuk mendegradasi senyawa-senyawa organic pada proses pembuatan kompos. Bern Micro adalah Microorganisme hasil seleksi yang dapat mempercepat proses pengomposan. Microorganisme ini merupakan mikroorganisme yang dapat melakukan fermentasi terhadap senyawa-senyawa organik melalui kemampuan lignolitik, selulotik, amilolitik, preteolitik serta fiksasi nitrogen nonsimbiotik. Mikroorganisme ini juga dapat melakukan fermentasi senyawa organic didalam tanah menjadi unsur organic, sehingga kesuburan tanah dan produktivitas tanaman bertambah. Aturan Pakai: Terhadap bahan organik yang telah dipersiapkan (bahan organik ukuran ≤ 5cm, pupuk kandang dengan perbandingan 1:3 atau sebaliknya) ditambahkan Bern Micro 0.2 – 1.0% (V or b). |

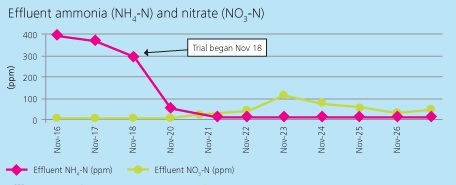

NITRIFIYING BACTERIA

| NITBACNitrifiying Bacteria Nitrifiying bacteria was added to the aeration basin over a ten day period, in addition to raising the mixed liquor pH to 7.7. During this period, the effluent NH4-N decreased by 97.5%, from 397 to 10 ppm. Nitrifiying bacteria’ biological program was easy to implement and provided significant benefits over other alternatives. Nitrifiying bacteria resulted in:

|

SOIL STABILIZER

SOIL STABILIZER

| PRODUK PENGERASAN JALANMenyediakan Produk Soil Stabilizer (Pengerasan Jalan) Soil stabilizer adalah bahan penstabil lahan dan pemadatan tanah (solidifikasi). Pada ketebalan 10 – 20 cm, campuran tersebut mampu menahan beban hingga 50 – 240 ton/m2 dengan karakteristik tanah tertentu. Produk ini berupa material ramah lingkungan yang terdiri dari garam/mineral anorganik. Komposisi ideal dalam penggunaan = 1 M3 tanah : 100 kg semen : 1 kg soil stabilizer : 100 liter air. Keunggulannya:

Klasifikasi kegunaanya:

|

FIRE EXTINGUISHERS.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)